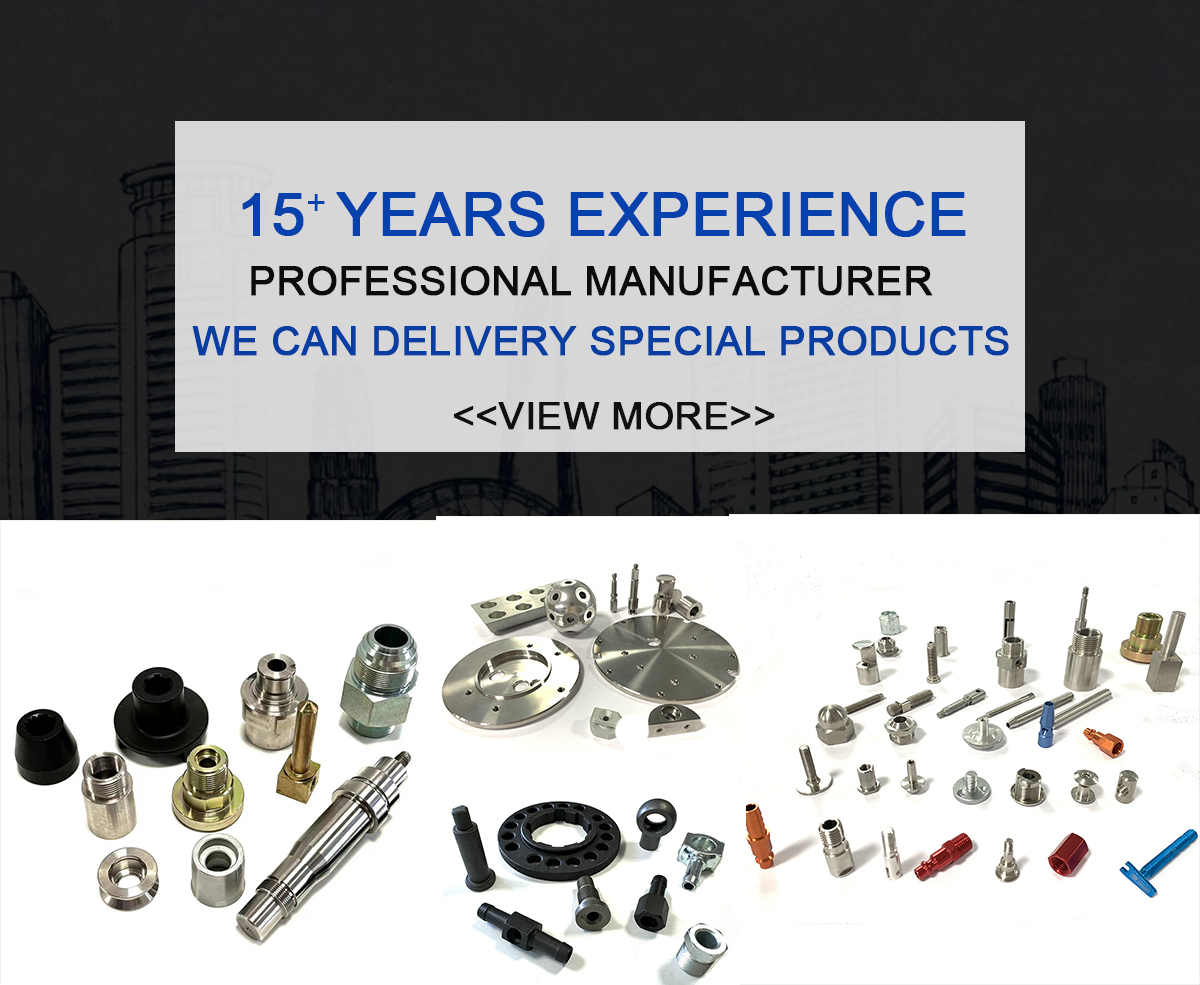

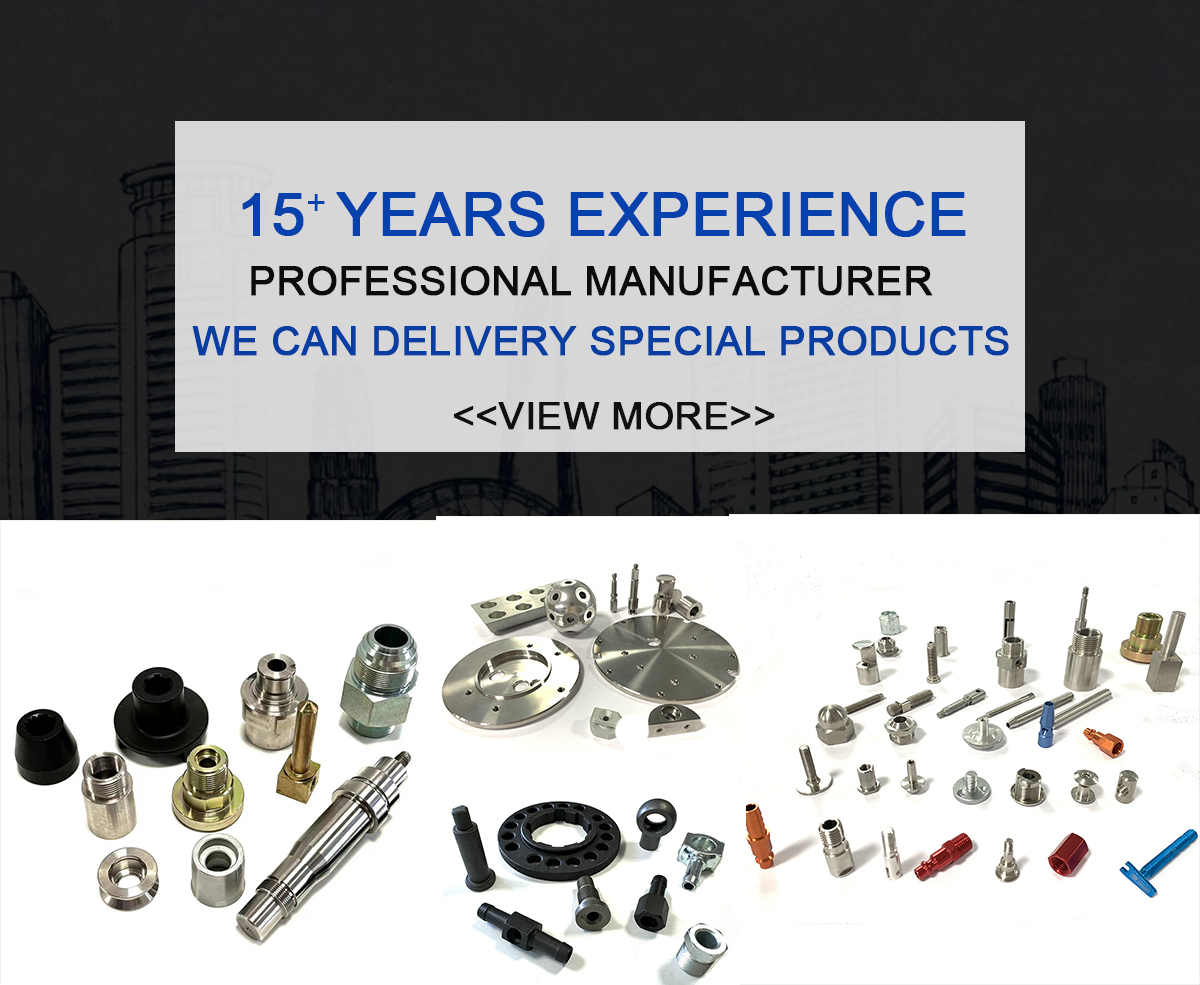

Product Introduction

This product is a CNC turning part .The materials include stainless steel, brass, carbon steel, and aluminum. This product undergoes CNC machining, including broaching, drilling, etching/chemical machining, laser machining, milling, wire EDM, grinding, and rapid prototyping.

This can be used in tractor, Agricultural machinery accessories...We also can produce according to your drawings or pictures.

Product Advantage

High-Precision Machining: CNC turned parts employ cutting-edge micro-machining technology to ensure dimensional accuracy up to ±0.005mm. Such precision is crucial in fields that demand high accuracy, like aerospace and medical equipment.

Customization Service: We offer comprehensive customization services, from material selection to finishing processes, tailored to client specifications. Our products cater to projects of varying complexity, meeting unique technical demands.

Technical Parameters

Parameter | Description |

Material | Brass, Stainless Steel, Carbon Steel, Aluminum |

Type of Processing | Broaching, Drilling, Etching/Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire ED etc. |

Precision | ±0.005mm |

Surface Finish | Plain |

Size | Customized |

Applications | Agricultural machinery accessories |

Product Uses

FAQ

Q: Are these CNC-machined parts suitable for special customization requirements?

A: Yes, we offer professional customization services based on design to meet your special needs.

Q: Are these products suitable for corrosive environments?

A: Yes, we offer various surface treatments, such as galvanizing or nickel plating, to enhance corrosion resistance.