In modern construction, industrial operations, and architectural projects, the reliability and longevity of hardware components are crucial for ensuring safety, stability, and cost-efficiency. Among the various types of fasteners available, DIN 444 stainless steel eye bolts have emerged as a preferred choice for engineers, architects, and procurement specialists. These eye bolts not only provide exceptional strength and load-bearing capacity but also combine corrosion resistance and eco-friendly material benefits, making them ideal for both indoor and outdoor applications.

The performance of a stainless steel eye bolt is influenced not only by the quality of the raw material but also by its manufacturing process and design. By selecting high-quality DIN 444 stainless steel eye bolts, professionals can achieve reliable, long-lasting solutions for structural support, lifting operations, and decorative installations.

1. Overview of DIN 444 Stainless Steel Eye Bolts

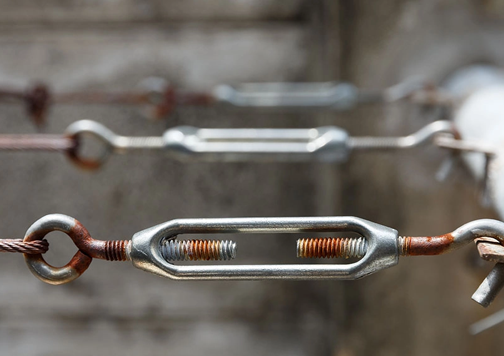

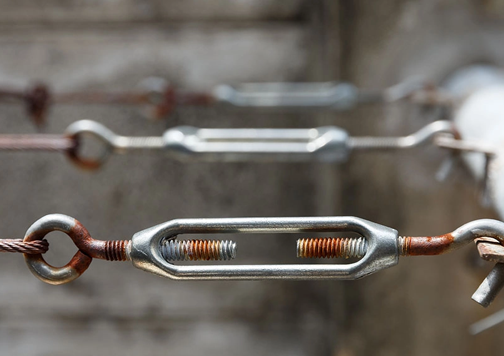

DIN 444 stainless steel eye bolts are specialized fasteners characterized by a looped head at one end and a threaded shank at the other. This simple yet effective design allows them to serve as secure attachment points for lifting, hoisting, anchoring, and connecting equipment or materials. Eye bolts are highly versatile, used across industries such as construction, manufacturing, shipping, and architecture. They provide safe and reliable support for suspended loads, structural elements, and fixtures while ensuring ease of installation.

These eye bolts are manufactured in compliance with DIN 444 standards, which guarantee dimensional accuracy, load-bearing capacity, and consistent quality. Available in sizes ranging from M5 to M39, they can also be customized to meet specific project requirements. Material selection is another key factor influencing performance. 304 stainless steel is commonly used due to its excellent corrosion resistance and general durability, making it suitable for most indoor and outdoor applications. For harsher environments, including marine and chemical settings, 316 stainless steel is preferred, as the addition of molybdenum enhances resistance to chloride corrosion and ensures long-term durability.

2. Durability of DIN 444 Stainless Steel Eye Bolts

Durability is one of the most critical factors when choosing hardware for construction and industrial projects. DIN 444 stainless steel eye bolts are engineered to withstand heavy loads and resist mechanical wear over time. The combination of high-quality stainless steel and precise manufacturing processes, such as cold forging and heat treatment, ensures a dense, strong, and structurally sound fastener.

High Load Capacity and Mechanical Strength

Eye bolts are frequently subjected to significant tensile and shear forces, particularly when used in lifting, hoisting, or structural applications. Cold forging enhances the metal’s internal density, while heat treatment improves toughness and fatigue resistance. As a result, DIN 444 stainless steel eye bolts can endure repeated stress cycles without deformation or failure. This high load capacity makes them ideal for:

Supporting heavy beams, steel frameworks, and scaffolding in construction sites

Anchoring machinery and industrial equipment

Securing suspended installations such as HVAC units, piping, or lighting systems

Long-Term Performance

The durable design of stainless steel eye bolts minimizes maintenance requirements and reduces the need for frequent replacements. This longevity translates to cost savings over the lifespan of a project while ensuring continuous operational safety. Projects in demanding environments, such as coastal construction or industrial facilities, particularly benefit from the extended service life of DIN 444 eye bolts.

3. Corrosion Resistance

Corrosion is a major concern for hardware exposed to moisture, chemicals, or harsh environmental conditions. Stainless steel inherently resists rust and chemical degradation, but DIN 444 stainless steel eye bolts take corrosion resistance a step further.

Material and Surface Protection

The use of 304 or 316 stainless steel, combined with protective zinc plating or polishing, ensures that eye bolts remain resistant to moisture, chlorides, and other corrosive agents. The precision manufacturing process further reduces micro-defects, which can act as initiation points for corrosion, thereby enhancing longevity and structural integrity.

Environmental Adaptability

Corrosion-resistant eye bolts are particularly important in environments such as:

Outdoor construction projects exposed to rain, humidity, and temperature variations

Coastal and marine settings with high salt concentrations

Industrial sites with chemical exposure

By resisting corrosion, these eye bolts maintain both safety and aesthetics over time, ensuring that structural connections and suspended installations remain reliable and visually appealing.

4. Eco-Friendly Aspects

Beyond durability and corrosion resistance, DIN 444 stainless steel eye bolts contribute to environmental sustainability. Modern manufacturing processes and material selection emphasize eco-friendly practices while maintaining high performance.

Sustainable Materials

Stainless steel is a fully recyclable material, and high-quality DIN 444 eye bolts are produced with minimal environmental impact. Choosing durable stainless steel reduces the frequency of replacements, thereby decreasing resource consumption and waste.

Environmentally Responsible Production

Leading manufacturers implement controlled production techniques that minimize emissions, reduce energy consumption, and adhere to green manufacturing standards. This ensures that the creation of high-performance eye bolts aligns with the growing demand for environmentally responsible industrial practices.

Long-Term Environmental Benefits

By combining durability, corrosion resistance, and sustainability, DIN 444 stainless steel eye bolts help reduce environmental footprints across construction, industrial, and architectural projects. Their long service life means fewer discarded components, lower maintenance requirements, and less material waste over time.

5. Applications Across Industries

DIN 444 stainless steel eye bolts are widely used across diverse sectors due to their strength, corrosion resistance, and eco-friendly properties. Key applications include:

Construction and Architecture

Securing beams, steel frameworks, and scaffolding

Suspending equipment such as lighting, HVAC systems, and piping

Supporting decorative installations and facade elements

Industrial and Manufacturing

Anchoring heavy machinery and equipment

Facilitating safe lifting and hoisting operations

Providing reliable attachment points for cables, ropes, and chains

Architectural and Decorative Installations

Hanging glass panels, art installations, and interior fixtures

Ensuring aesthetic appeal without compromising structural integrity

Customizing dimensions and finishes to meet unique design requirements

These applications demonstrate the versatility of DIN 444 stainless steel eye bolts and highlight why they are a preferred choice for professionals seeking strength, reliability, and sustainability.

6. Key Considerations When Selecting DIN 444 Stainless Steel Eye Bolts

Selecting the right eye bolt is essential for maximizing performance and safety. Consider the following factors:

Material Grade: Choose 304 for general applications and 316 for marine or chemically harsh environments.

Size and Thread Type: Ensure the bolt matches the load requirements and installation specifications.

Load Capacity and Safety Factors: Verify working load limits and structural requirements.

Environmental Conditions: Consider indoor vs. outdoor use, chemical exposure, or coastal installation.

Eco-Friendly Manufacturing: Prioritize bolts produced with sustainable materials and processes for long-term environmental benefits.

By carefully evaluating these factors, engineers and architects can ensure that their projects benefit from durable, corrosion-resistant, and eco-friendly fastening solutions.

7. Conclusion

DIN 444 stainless steel eye bolts are essential hardware components that deliver unmatched durability, corrosion resistance, and environmental sustainability. Their robust design, precision manufacturing, and material quality make them ideal for construction, industrial, and architectural applications requiring reliable load-bearing capacity and long-term performance.

By choosing high-quality eye bolts and considering material grade, load requirements, and environmental conditions, professionals can ensure safety, reduce maintenance costs, and achieve long-lasting results. For engineers, architects, and procurement specialists seeking premium stainless steel hardware, investing in DIN 444 eye bolts offers both operational efficiency and eco-friendly benefits.

To explore high-performance, customizable solutions and enhance the safety and longevity of your projects, consider contacting Ningbo Yinzhou Gonuo Hardware Co., LTD., a trusted provider of durable and sustainable stainless steel eye bolts.